Hidden gems

Jewellery making is a special and specialised art form that these local businesses have mastered with skill and creativity.

Words Nicky Adams

The craft of jewellery making, or manufacturing, is ancient and highly skilled, and like any art it is one that combines talent, skill and often years of experience. While there are many jewellery shops to choose from, not all of these are manufacturing jewellers (that is, where the jeweller makes the pieces themselves). The jewellers with an atelier are the places you can go to have bespoke pieces designed or find pieces that are truly handmade. UNO spoke with some local jewellery manufacturers about their craft.

Jewellers Boutique Bethlehem

Three years ago, after 12 years of owning Bethlehem Jewellers, a full-service village jewellery store, Adrian and Helen Redding identified that, in Helen’s words, “The industry was at a tipping point. There’s a huge amount of change and we were keen to move ahead of it.” Adrian clarifies, “With chain stores becoming more generic, we wanted to take the service back to working on those relationships with people; that’s how we can understand the vision of what they would like created.”

In order to do this, they needed to provide the environment where they could have those conversations, hence a move of premises, a change of focus, and realignment of their business. The dream was to become a bespoke manufacturing jeweller providing “consultation and development of design, from procuring the right gems to creating the piece.” With an existing thriving business, and loyal clientele, Adrian and Helen felt confident to take the next step, and opened a new, exclusive premises in Bethlehem that operates on a combination of restricted opening hours and an appointment basis. A stylish, intimate boutique destination with a workshop on site, here they sell a curated selection of fine jewellery and take on a limited amount of specialist repairs – the real emphasis is on bespoke manufacturing.

A love of the traditions of jewellery making is at the core for Adrian, who, after 29 years in the business, has a deep passion for his craft. He was literally plucked from Otumoetai College, where his skill at engineering, woodwork and metal work had identified him as an emerging talent. He was then offered an apprenticeship as a manufacturer of fine jewellery by respected Tauranga jeweller David Peet. Jewellery making, Helen notes, “is like engineering in miniature form – looking at how to build something so it is strong, durable and will last, and then making it beautiful, so it’s really a combination of engineering and design.” Adrian chimes in: “A fusion of aesthetics to structure.” For the Reddings, the art of designing that treasured custom piece is a skill that has come with experience. The result, is why Adrian is an award-winning jeweller – because what he creates “is not just unique, it is the perfect balance of proportion, and beauty, custom-designed for the individual to wear every day.”

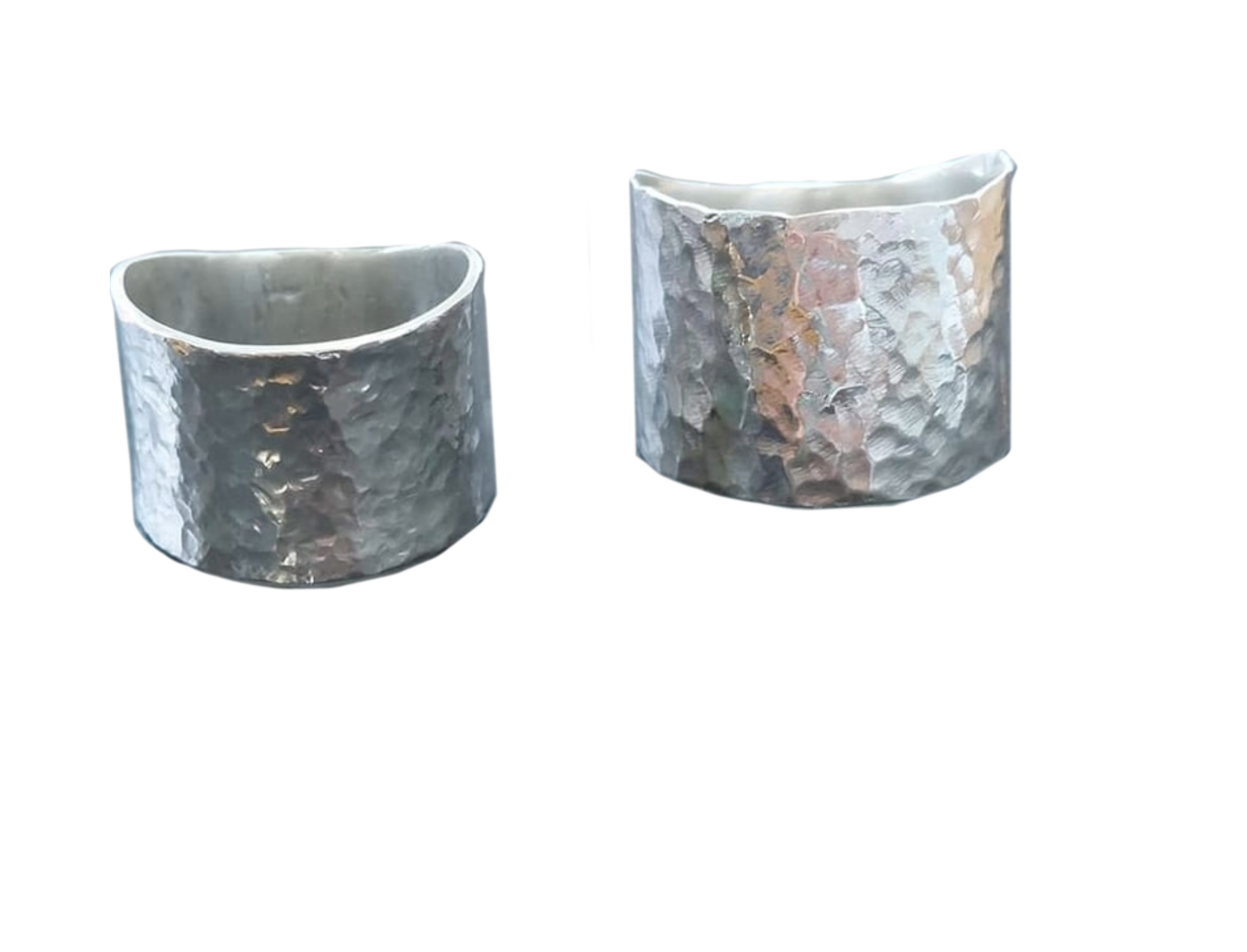

Alexandra Mostyn Jewellery Papamoa

Working from her small workshop in Pāpāmoa, Alexandra is a silversmith. This love of silver is rooted in a combination of practicality, cost, and personal preference. ”Silver is visually cool… Set with beautiful pastel stones, the two just marry together so beautifully.” Alexandra moved to New Zealand in 2010 from the UK, where she had studied silversmithing and jewellery design at Kensington & Chelsea College. She then refined her skills at Guildhall University at Whitechapel, completing a pre-apprenticeship while working on the retail side for prestigious jewellers Tiffany &Co and Theo Fennell. Jewellery making as a business only happened years later, when suddenly the timing felt right. Turning her shed into a studio, she started creating – and, she says with a bit of surprise, “people said, ‘I like that, can I buy it?’ It’s all just through word of mouth and Instagram.”

Alexandra enjoys every element of the making process. “I love sitting down with clients, where I get the essence of them – we talk about design and stones, then I get into the studio. I get lost in the creativity of it all – there’s the problem-solving (if the cut of a stone isn’t right and I have to vary the design), lots of swearing along the way, then the moment when they pick up the ring and hug you.” The relationship side of it all is hugely inspirational to Alexandra, as is the concept of being able to upskill and learn. As a result, she started holding workshops, which she now runs on a regular basis from the Incubator Hub in Historic Village. She fizzes as she talks about the workshops, “I make them really fun and inclusive. I love the energy I get from my crowd; I love that these people are here to learn to create and are really proud of what they’ve made.”

Alexandra is a huge believer in the connection between herself, the piece, and the client: “All the jewellery I make, I would personally wear.” The semi-precious stones she uses (aquamarine, opal and peridot are among her favourites) reflect this – “I know I’m going to sound like a tree-hugger, but every stone has different properties with different energies. It’s really important to get it right.”

f. alexandramostynjewellery

Did you know?

New Zealand jewellery is held to higher standards than jewellery manufactured overseas.

When purchasing a piece, take into account whether the ring/bangle/chain you are looking at is solid or hollow – it’s easy to forget that you’re not always comparing like for like.

Think about the quality of the stone; whether it’s synthetic or natural, a real diamond or a lab diamond, consider size versus higher grade, which is less likely to fracture.

Artisan Manufacturing Jewellers

Trained in Auckland under the guidance of two ex-Hatton Garden Jewellers, Andrew Linn is an award-winning jewellery manufacturer who has been in the trade for 35 years. It’s an industry in which the combination of experience and skill can be seen in the workmanship, one glance in the display cabinet gives a clear reflection of his talents. Andrew and wife Kay run a manufacturing and retail store, where they hold to high standards. “We see a lot of low-grade stuff from overseas but we tend to go down the higher end because if something’s low-grade and full of inclusions, if it gets knocked it can fracture.”

Andrew sees a lot of people who come in to remodel a piece of jewellery. “Lots of remakes, all the old broken jewellery. We’ll do 3D images for them, we’ll sit down and spend time going through books. Most people will want to use Grandma’s gold or Grandma’s diamond.” Bespoke pieces are also created from scratch, and the jewellery in the cabinet provides inspiration – “We don’t have a huge range, just basic to give people ideas. If you don’t have stock people struggle to see what you can do. That goes for your handmade chains, anything.”

“Everything is one-off and unique; there will be other cluster rings, for example, but none the same,” says Andrew. Alongside all of this, Andrew works on a steady stream of repairs. Much of the work is done by hand, using the same traditional methods he learned as an apprentice. There are innovations in the jewellery industry: “Technology is starting to take over, 3D for drawings and printings (to use as a mould) – but the cost in our trade to do it is really expensive at the moment. But it will come down. 90% of our stuff is done by hand. I have several hundred patterns and I’ll cast a replica; as much as we handmake, we do cast some stuff.” Trends don’t really affect their market; however, at the moment, Andrew says, “We’re doing a lot more platinum work, which is more affordable than it used to be.” Andrew and Kay believe in traditional skills and traditional values: “Anything I make I look after for life. So if you want it cleaned, or checked – well, unless it has been run over by a bus, of course!”

Caring for your jewellery

Jewellery needs regular upkeep. It is, says Helen from Bethlehem Jewellers, “like changing the tyres of a car.” Try to avoid wearing rings when gardening or to the gym, and remove jewellery in bed, as cotton is actually very abrasive. Andrew from Artisan also uses the car analogy, saying, “You wash a car to clean it, you polish it for shine.” If you clean your jewellery at home, use a soft brush, warm soapy water, and a tissue to drain the water away. All the jewellers recommend avoiding hacks you’ve seen on the internet (don’t put in the microwave or boil in gin). When it comes to jewellery, the chances are what you have is priceless to you – it’s the ultimate emotional investment.